In recent years, many people have been trying to make furniture more convenient to use, especially some furniture that needs to be moved

frequently. After installing appropriate casters, the trouble of frequent moving can be avoided.

So, in the huge furniture caster market, how can we avoid choosing the wrong inferior furniture casters?

Load-Bearing Capacity Test

A load-bearing capacity test is related to the safety hazards of using furniture casters. Generally , the load-bearing capacity limit difference

of furniture casters is the sum of 3 casters.

However, it is better to purchase 4 casters. This can also avoid overweight and other situations during daily use. When choosing furniture

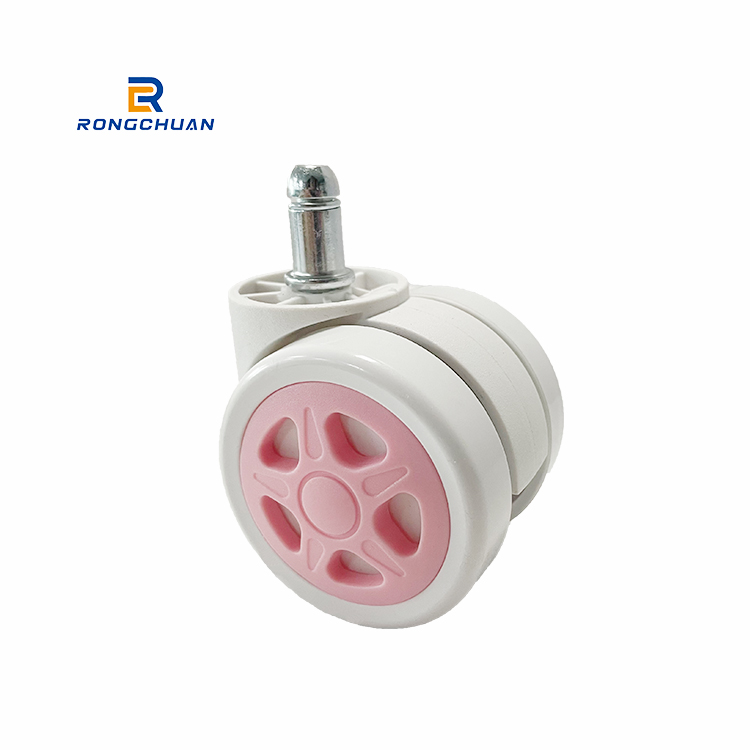

casters, it is not enough to choose the right load-bearing capacity of the casters. The design style and material of the furniture casters

are also the top priority.

Size Selection When choosing casters, you must clearly understand the size of the casters, which is the diameter of the furniture casters. Common furniture

caster sizes are generally between 1 and 2.5 inches. This size can ensure that the height of the furniture can be changed to a minimum while

meeting the convenience needs of the furniture.

The Manufacturing Material of Furniture Casters

Currently PU and nylon are the main materials.Different casters have different application ranges and design parameters. PU casters are

polymer materials, which are more suitable for use in poor road construction environments. This type of casters has a relatively high

hardness, but it is not suitable for use in chemical environments, while plastic casters are suitable for use in chemical environments.

Although casters are small, they can directly affect the convenience of our lives, and more importantly, they will greatly affect the safety

of furniture use. The smallest parts often determine the overall practicality and safety of furniture. Therefore, you must not be careless

when choosing furniture casters.

Post time: Sep-21-2023